The estimated total overhead costs are then divided by the estimated total of the allocation base. This activity base is often direct labor hours, direct labor costs, or machine hours. Once a company determines the overhead rate, it determines the overhead rate per unit and adds the overhead per unit cost to the direct material and direct labor costs for the product to find the total cost. The formula seems simple – total overhead costs divided by an allocation base like direct labor hours. However, accurately calculating overhead normal balance rates involves breaking down costs and choosing the right allocation base.

Examples of Overhead Rates

For example, if a firm estimates $500,000 in annual overhead costs and forecasts 20,000 direct labor hours, the rate is $25 per direct labor hour. This rate systematically funnels dispersed indirect costs into the cost of the output. Consistent application ensures every job bears its proportionate share of the operating burden, facilitating cost comparisons. The biggest mistake is choosing an allocation base that doesn’t actually correlate with how overhead costs are incurred. For example, if you allocate based on direct labor hours but most of your costs are related to running automated equipment, your product costs will be distorted. The key is to select an allocation base that has a logical relationship with your overhead costs.

- After reviewing the product cost and consulting with the marketing department, the sales prices were set.

- For example, let’s say the marketing agency quotes a client $1,000 for a project that will take 10 hours of work.

- If you’d like to learn more about calculating rates, check out our in-depth interview with Madison Boehm.

- The overhead rate is calculated by dividing total overhead costs by an appropriate allocation measure such as direct labor hours.

- As the production head wants to calculate the predetermined overhead rate, all the direct costs will be ignored, whether direct cost (labor or material).

Key Takeaways

The Applied Overhead Calculator is a crucial tool in manufacturing and project management that helps businesses allocate overhead costs accurately based on actual activity levels. This ensures that products are priced appropriately and that financial planning is based on realistic cost assessments. Properly calculating and applying overhead rates is an important accounting process for businesses to absorb indirect costs into their job costing system and product pricing.

Calculations

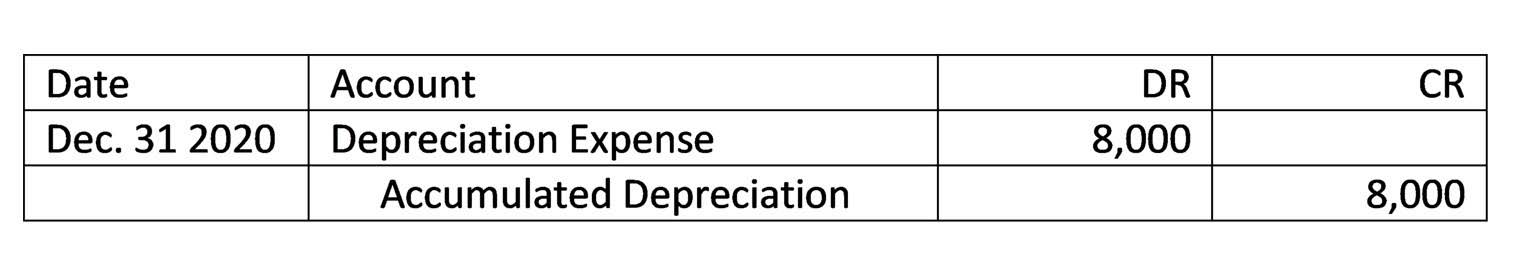

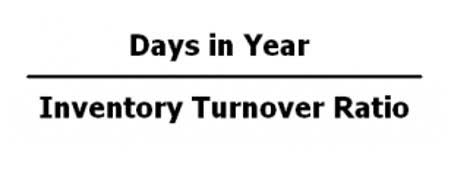

Using a predetermined overhead rate allows companies to apply manufacturing overhead costs to units produced based on an estimated rate, rather than actual overhead costs. This rate is then used throughout the period and adjusted at year-end if necessary based on actual overhead costs incurred. Before the start of the year, you calculate your total estimated manufacturing overhead costs. These might include things like indirect labor, indirect materials, utilities, rent, and depreciation on your factory machines – costs which are difficult to attribute directly to individual products. A predetermined overhead rate is a rate used to apply manufacturing overhead to products or job orders and is established before a period begins.

This rate is calculated by dividing the estimated manufacturing overhead cost for a period by the estimated total units in the allocation base for that same period. One more approach is to calculate the plantwide overhead rate using an alternative approach or direct cost method. To calculate this, we first need to identify the total direct cost of production and the total overhead cost for the specific period. Thus, this total overhead is divided by the total direct cost to ascertain the single plantwide overhead rate. Assume that management estimates that the labor costs for the next accounting period will be $100,000 and the total overhead costs will be $150,000.

Using the Wrong Allocation Base

The plantwide overhead rate might not help obtain exact figures, but the estimates are efficient enough for better planning. Predetermined overhead rate is the estimated overhead that will allocate to each product at the begining of accounting period. It is equal to the estimate overhead divided by the estimate production quantity.

The overhead rate has limitations when applying it to companies that have few overhead costs or when their costs are mostly tied to production. Also, it’s important to compare the overhead rate to companies within predetermined overhead rate formula the same industry. A large company with a corporate office, a benefits department, and a human resources division will have a higher overhead rate than a company that’s far smaller and with fewer indirect costs. As you can see, calculating your predetermined overhead rate is a crucial first step in pricing your products correctly. For instance, if the rate is $30 per machine hour and a job required 15 machine hours, the applied overhead is $450. This $450 is added to the job’s direct material cost of $1,200 and direct labor cost of $800, resulting in a total job cost of $2,450.

C. Accurate Product Pricing

Overhead rates are an important concept in cost accounting and business analysis. By properly calculating and applying overhead rates, businesses can accurately assess the true costs of their operations. This rate would then charge $4 of overhead to production for every direct labor hour worked. It allows overhead to be assigned to production based on activity (DLHs), providing insight into Medical Billing Process profitability across products. In summary, overhead rates have a sizable impact on a company’s key financial statements and decisions. Investing time into overhead analysis and accurate calculation of rates leads to better accounting and superior business management.

After going to its terms and conditions of the bidding, it stated the bid would be based on the overhead rate percentage. Therefore, the one with the lower shall be awarded the auction winner since this project would involve more overheads. Then, they’ll need to estimate the amount of activity or work that will be performed in that same time period.

The Importance of Accurate Overhead Rate Calculation

- It is often difficult to assess precisely the amount of overhead costs that should be attributed to each production process.

- This rate is used to allocate or apply overhead costs to products or services.

- It allows overhead to be assigned to production based on activity (DLHs), providing insight into profitability across products.

- Variable overhead costs fluctuate directly with activity levels, such as the cost of indirect supplies or quality control inspections.

- This means that for every dollar of direct labor cost a production process uses, it will use $1.50 of overhead costs.

That’s why it’s important to get to know all of the different terminology relating to accounting, and how these financial metrics can be used to assess the financial health of your business. E-commerce businesses typically have different overhead structures – they might have higher technology and website maintenance costs but lower physical store expenses. Carefully tracking overhead expenses is key for small businesses to optimize costs. This involves categorizing all overhead costs and regularly analyzing them to identify potential savings.

Leave a Reply